Shutter Dyeing area: Manual spraying and fine finishing create excellent quality

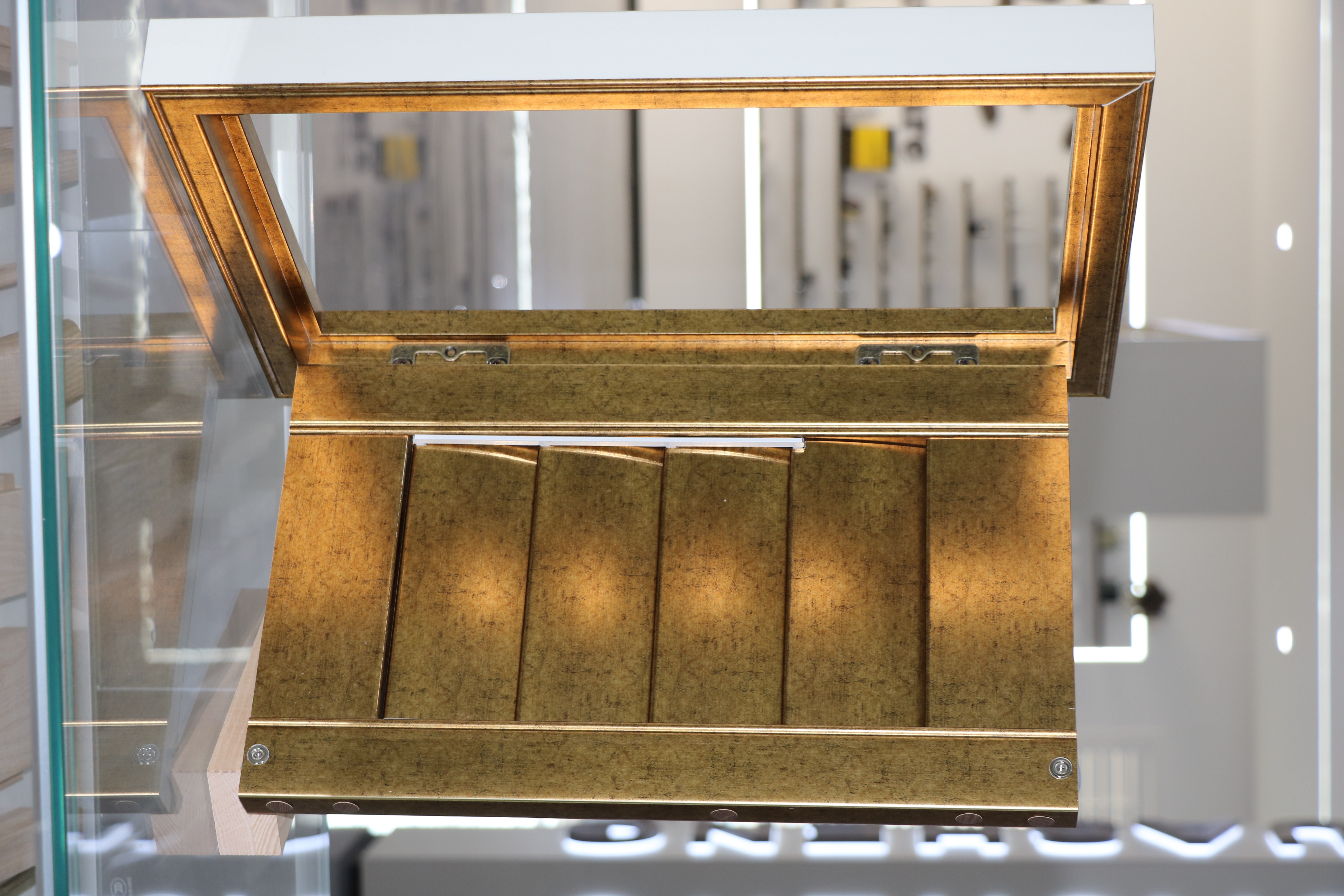

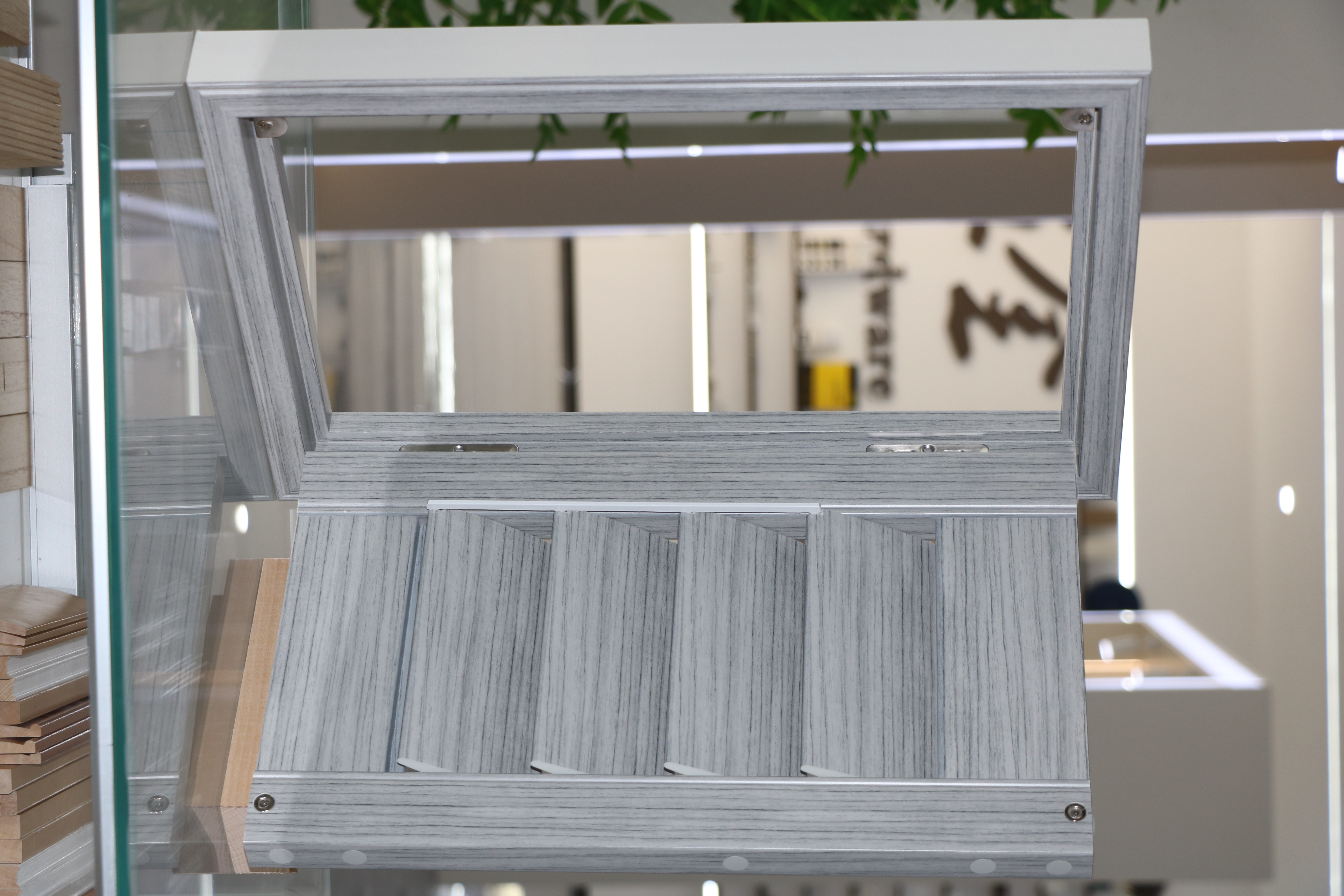

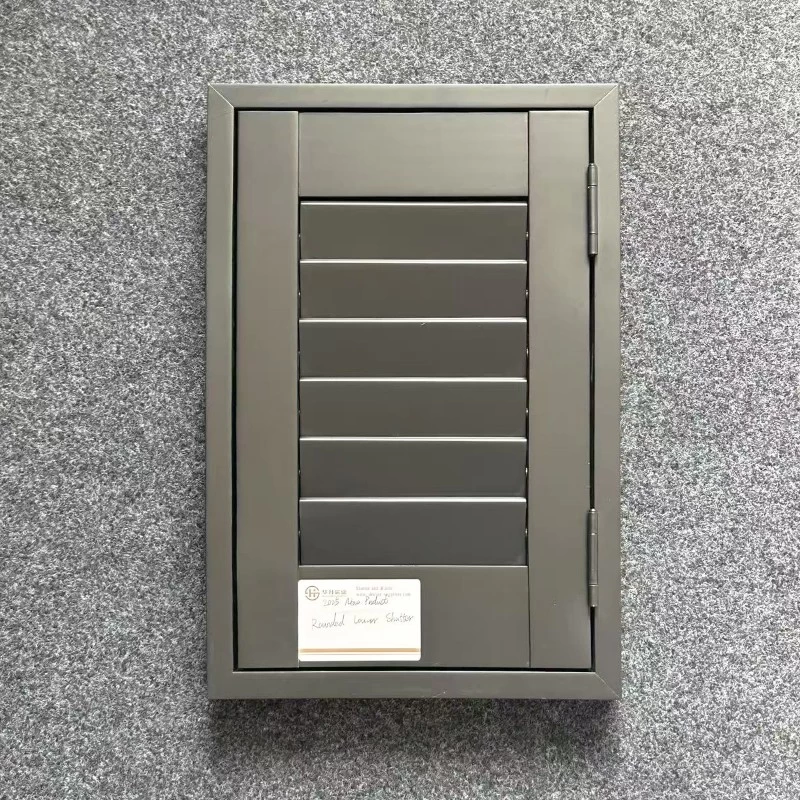

On Shutter production line of Huasheng Industry, dyeing area is the key link to ensure uniform color and excellent texture of products. Our traditional hand-painted process combines modern technology with craftsmanship to ensure that each Shutter product delivers high quality visual quality and durability.

Huasheng's dyeing area uses a manual spraying process to ensure that each shutter component absorbs the primer evenly. This manual spraying method allows the paint to be more evenly covered on the surface of the material. The workers are skilled in spraying techniques to ensure that the color of each product is consistent and the brightness is uniform, laying a solid foundation for the subsequent finishing process.

After the painting is completed, the retouching process is the key step to ensure the final effect of the product. According to the unique texture and color needs of each wood, skilled workers make precise color corrections to the material. Workers will manually adjust the color concentration and shade according to the individual needs of customers, so that the product can achieve the best visual effect. This process not only enhances the visual beauty of the product, but also ensures that each shutter is evenly colored and naturally textured, meeting customers' demands for detail and high standards.

The combination of manual spraying and retouching not only gives Huasheng's Shutter products an excellent appearance and color, but also reflects our pursuit and insistence on product quality. Each process is carefully polished to ensure that the product always maintains excellent durability and visual effects in daily use.