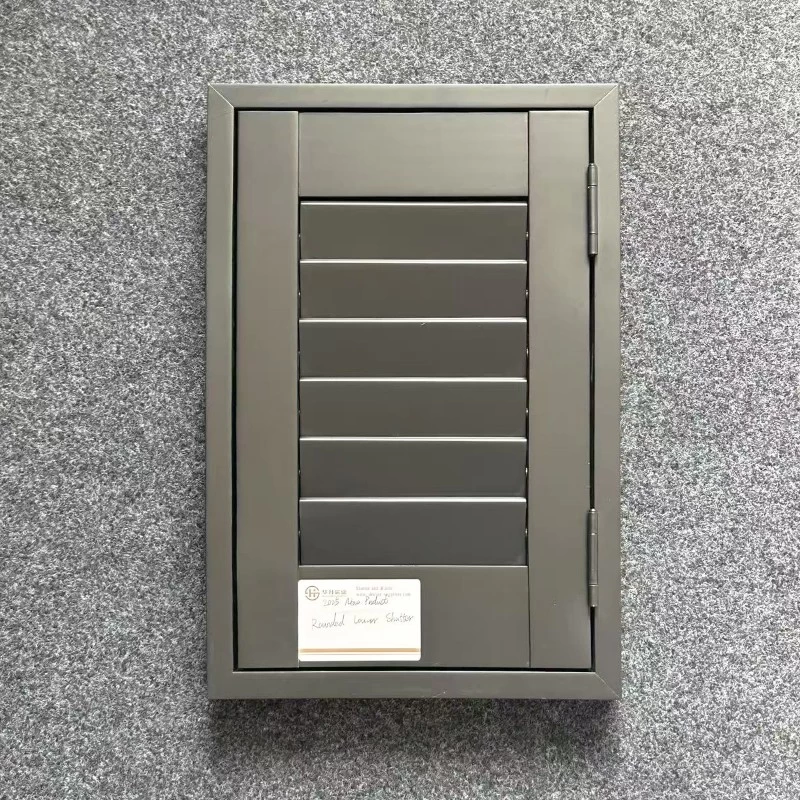

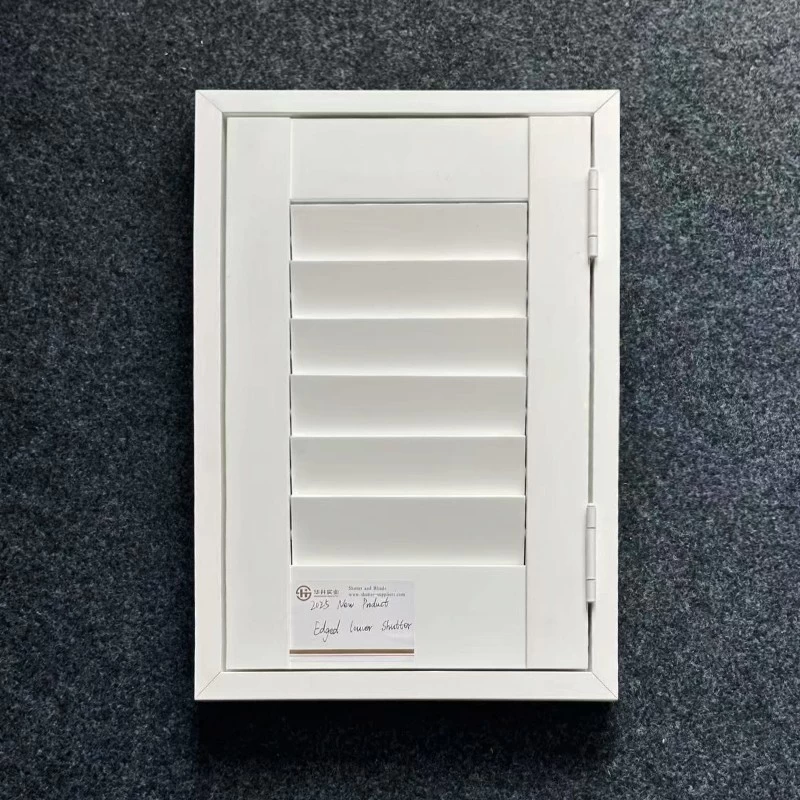

HuaSheng Aluminium Shutter Louver Powder Coating Technique

HuaSheng has advanced process technology, which enables them to become a leader in the Shutter industry. Recently, aluminum alloy breathable windows have become a hot topic,HuaSheng Having a professional sales team and R&D team,Developed Powder Coating Technique. This technology is very good, it can produce a lot of goods in a day, Let's start talking about the advantages of this technology.

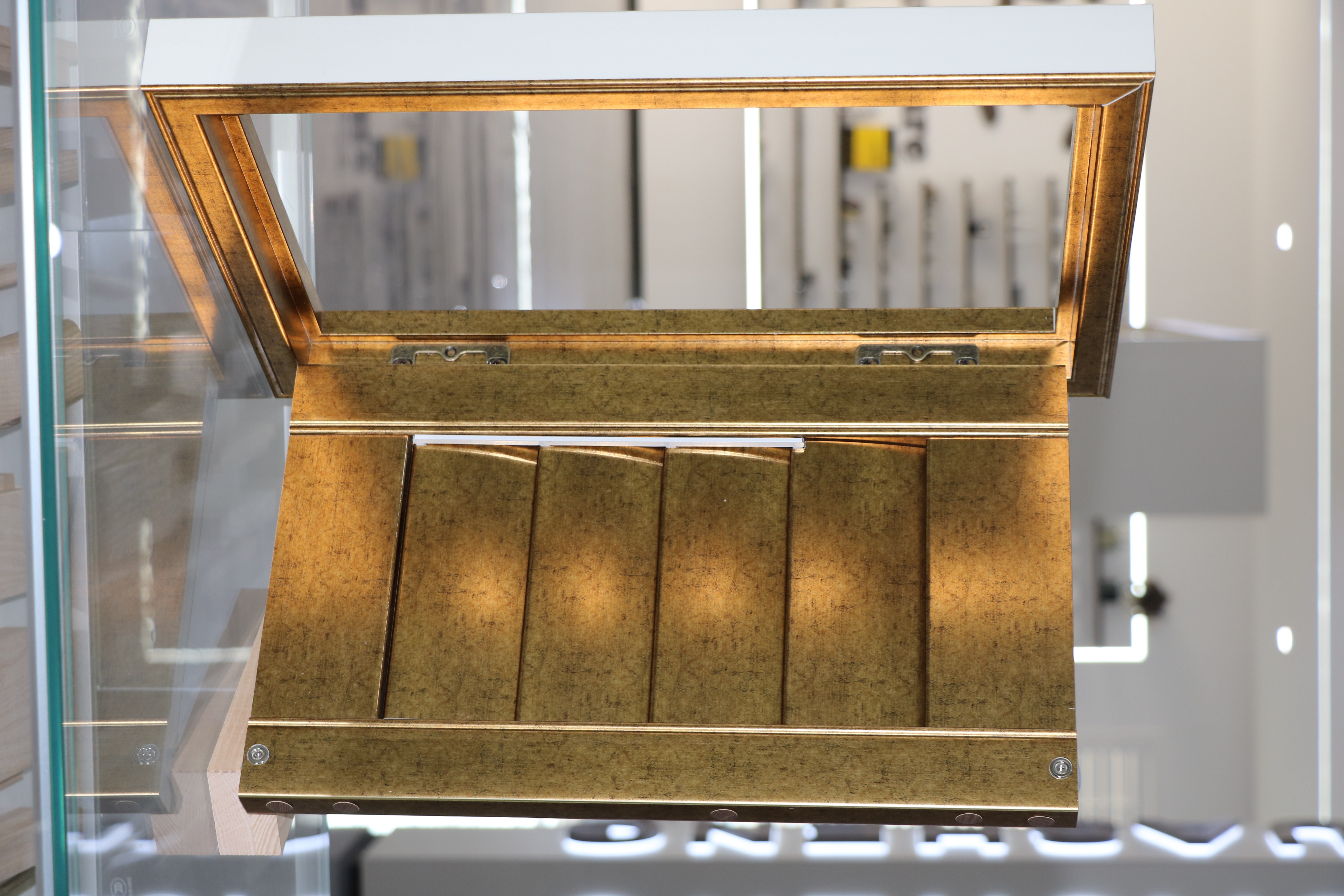

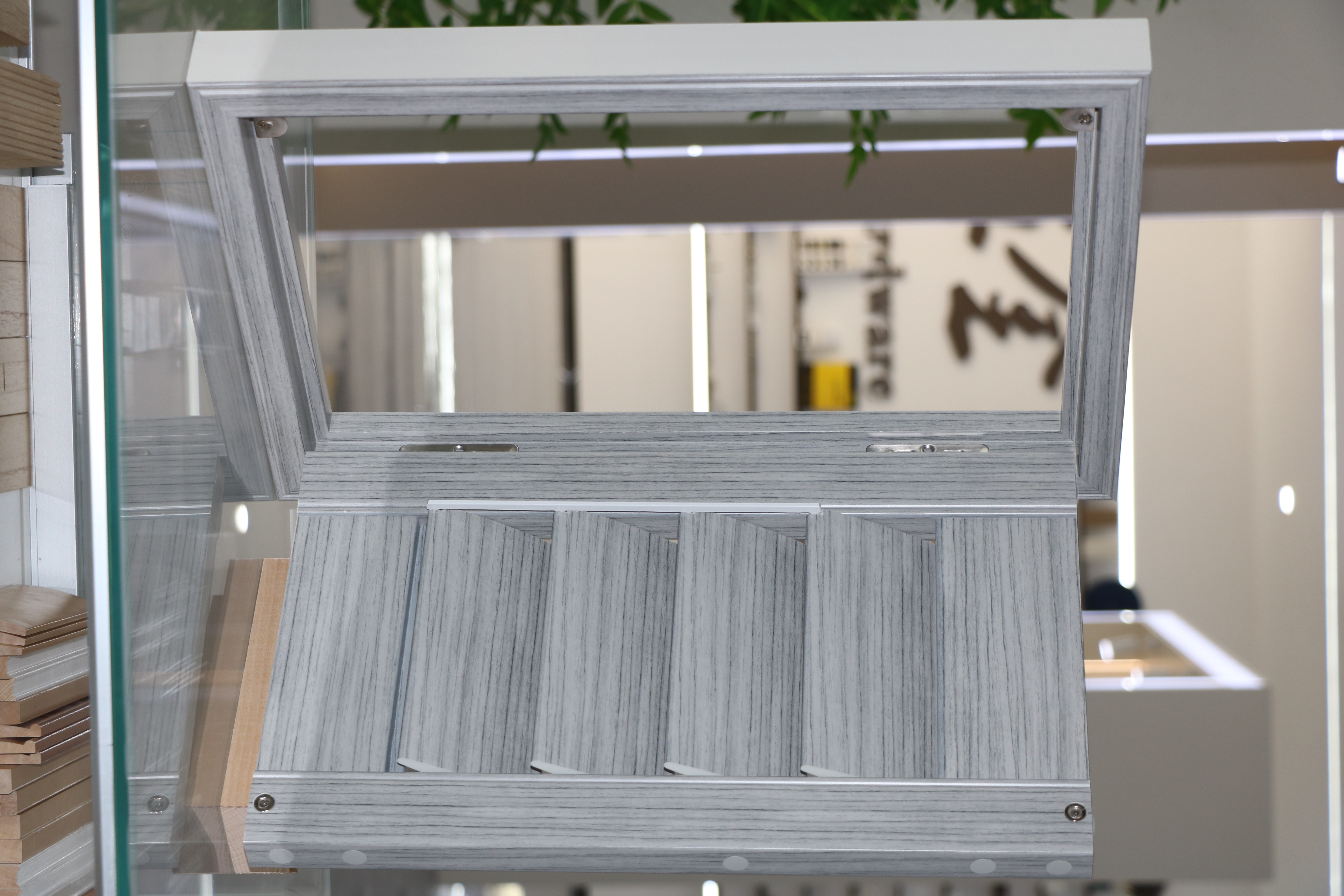

HuaSheng Can select polyester powder coatings with good weather resistance and appropriate glossiness based on Shutter's usage environment and customer color requirements. For example, for Shutter used in Outdoors, polyester powder with higher weather resistance can be selected, and common colors such as white and gray can be chosen according to the overall architectural style.

The powder spraying process is relatively simple to operate, with fast spraying speed, and can complete a large amount of Shutter Louver spraying work in a short period of time, improving production efficiency and shortening production cycles.

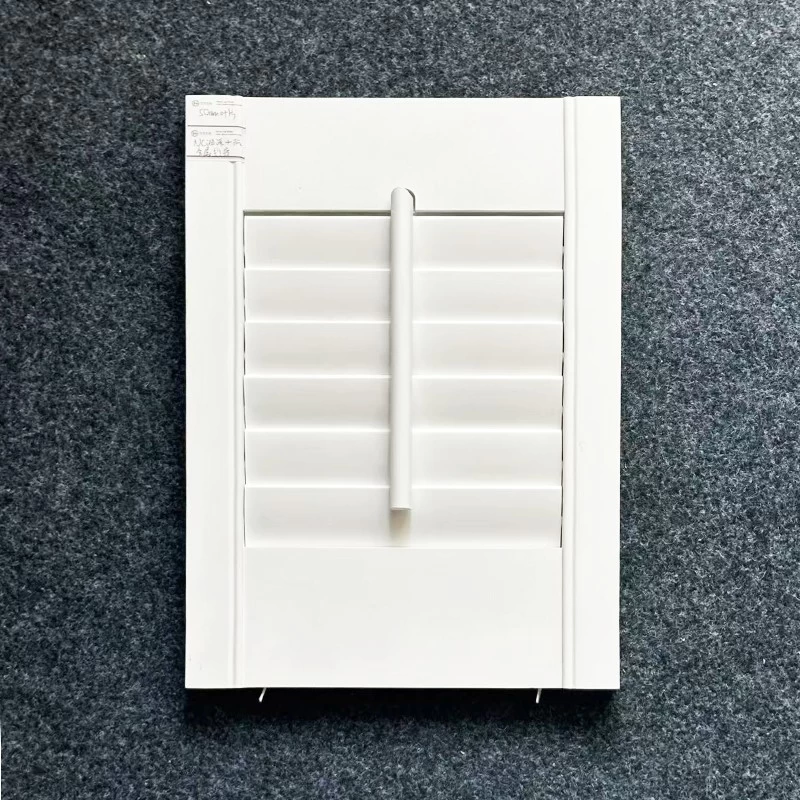

Starting from one end of the Louver, spray in a straight line back and forth to ensure uniform coating thickness. Generally, 2-3 layers of powder need to be sprayed, with a 5-10 minute interval between each layer of spraying.

Adjust the air pressure of the spray gun to 0.4-0.5MPa, keep the distance between the spray gun and the Louver at 180-220mm, and control the movement speed of the spray gun at 30-50cm/s to ensure that the powder is evenly sprayed on the surface of the Louver. After completing the Louver, the HuaSheng R&D team will conduct testing.

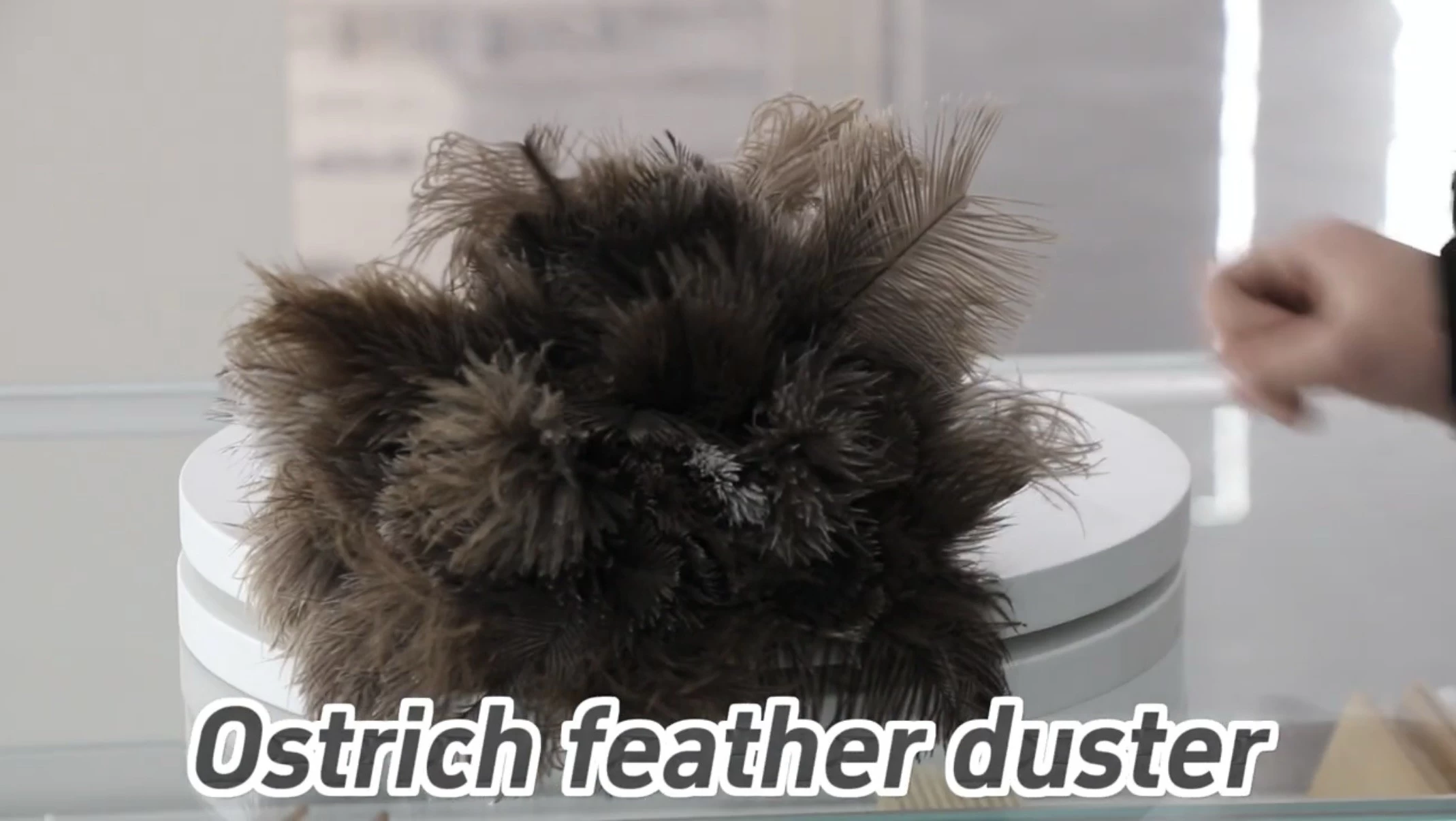

Firstly, conduct a visual inspection to observe the surface of the Louver coating with the naked eye. It should be smooth and flat, without obvious scratches, pinholes, or other defects. The color should be uniform and consistent, with no color difference.

Adhesion test, using the grid method, cut 1mm × 1mm squares on the surface of Aluminum Louver coating with a cutting tool, then stick and peel off with tape, observe the peeling of the coating inside the squares, and the adhesion of the coating should reach level 0 or level 1.

Corrosion resistance test, based on the usage environment of Shutter, choose to conduct neutral salt spray test or wet heat test. For example, for Shutter used in outdoor environments, a neutral salt spray test should be conducted for 48-96 hours, and the coating should have no obvious corrosion, blistering, peeling, or other phenomena.

Color difference test, using a professional colorimeter for comparison, comparing the Louver that passes the test with the Louver that is currently being tested. A color difference density of less than 0.1 is considered qualified. Each measurement point should be measured at least 3 times, and the average value should be taken as the color data for that point to reduce measurement errors.